Vortex induced vibration of a 2D cylinder by Michael Alletto

- contributor: Michael Alletto

- affiliation: WRD MS

- contact: click here for email address

- OpenFOAM versions: v2006

- Published under: CC BY-NC-ND license (creative commons licenses)

Go back to Collection by authors.

Go back to Meshing.

Contents

Vortex induced vibration of a 2D cylinder

You can download the case file https://gitlab.com/mAlletto/openfoamtutorials/-/tree/master/transverseRe100m*10] here.

Introduction

In this tutorial we will examine the capability of OpenFOAM to simulate the vortex induced vibration on a circular cylinder in a 2D laminar configuration. The cylinder is free to vibrate in stream wise and in transverse direction. This kind of flow configuration is often used to validate codes which aim to describe the interaction of a fluid with a solid structure (see e.g. [3],[6]).

Besides that, this configuration is used to answer fundamental questions of the basic physical mechanisms playing a role in the interaction between the flow and the solid body (see e.g. the review of [8]). Recent studies concentrate on the phenomena which lead to large amplitude oscillation of the cylinder and the synchronization of the vortex shedding frequency with the natural frequency of the spring-mass-damper system (see [1],[5]).

This tutorial is the final tutorial of a series of three which aims to illustrate how to validate a complex simulation task: It is convenient to break the problem first down into smaller easier sub tasks. In our example series before simulating the final problem of the vortex induced oscillations of a circular cylinder, we first simulated a fixed cylinder (see [1]), than a moving cylinder with a prescribed motion (see [2]), after that we checked the performance of the six degree of freedom body solver against an analytical solution (see [3]) and only as last point we tackled the simulation of the cylinder mounted elastically in a moving fluid. With this kind of procedure it is much easier to isolate eventual errors of the settings or maybe also bugs in the underlying code.

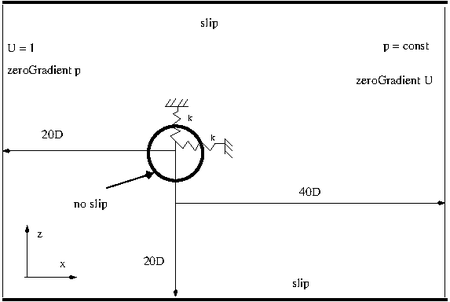

Set up

The next figure shows the setup of the simulation: At the inflow a uniform velocity of Uoo = 0.0656 m/s in x-direction is applied. The pressure is set to zero gradient at this boundary. At the top and bottom walls a slip boundary condition is applied. At the outlet the pressure is to be set equal to zero and for the velocity a zero gradient boundary condition is applied. The kinematic viscosity v = 1.05 x 10-6 m2/s is set in order that the Reynolds number Re = Uoo D / v based on the cylinder diameter D = 0.0016 m is equal to Re = 100. For this Reynolds number the flow over a stationary cylinder is two dimensional. For this reason the flow is assumed to be two dimensional. This is imposed by using only one cell in span wise direction and setting both boundary conditions in this direction to the type empty. At the cylinder wall a no slip boundary condition is applied for the velocity and zero gradient for the pressure. The cylinder is free to oscillate in x- and y-direction. In this direction a linear spring restrain type is applied. The linear damping is set to zero in order to be comparable with the reference simulation of [7]. The domain extends 20 D in upstream direction, 40 D in downstream direction and 20 D in both lateral direction. For this size of the computational domain [4] found that the results are almost independent of the location of the boundaries.

Four different non dimensional velocities are computed: U* = Uoo/(fn D) = 4, 4.8, 5 and 8.5. Uoo is the incoming flow velocity and fn = &omega/(2 π) = (k / m)0.5/(2 π) is the natural frequency of the spring-mass system. The lowest and highest non-dimensional velocity correspond to cases in [7] where the shedding frequency is not synchronized with the spring-mass system and therefore low amplitude oscillation of the mass occur. A U* = 4.8 correspond to the onset of synchronization with large amplitude oscillation (y/D approx 0.6) in the reference experiment. A U* = 5.5 correspond to a region in the middle of the synchronization regime. Also for this case the reference experiment reportes large amplitude oscillations. Having defined the diameter D of the cylinder, the incoming flow velocity Uoo and the mass m = 0.03575 kg, after that one can determine the four different linear spring constants k = $148.2, 102.97, 78.42 and 32.83 N/m for a non-dimensional velocity of U* = 4, 4.8, 5.5 and 8.5, respectively. The last non-dimensional parameter to match is the non-dimensional mass m* = m / mf = 4 m / (ρ D2 H). H = 0.12 m is the height of the cylinder. In order to match this non-dimensional parameter the density is set to 14817 kg / m3.

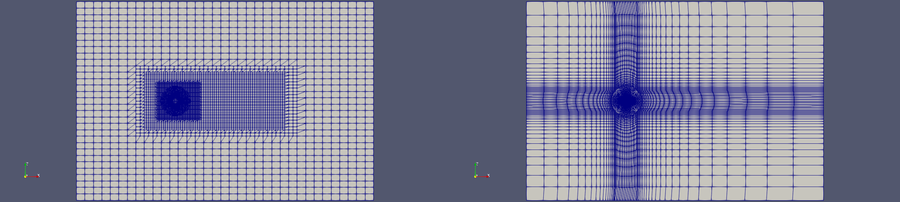

Mesh generation

The next figure shows the two mesh types compared: On the left the overset mesh and on the right the morphing mesh. The overset mesh consists in a cylindrical mesh immersed in different rectangular regions. The morphing mesh also consists in a cylindrical region in the center which is connected with hexagonal cells to the outer boundaries. Note that the cylindrical regions in the overset mesh and the morphing mesh are identical for better comparability of the results. The two mesh types (overset and morphing mesh) are essentially taken from this tutorial: [4]. For this reason how they are generated is not described in more detail.

Simulation set up

The next listing show the dynamicMeshDict for the overset mesh. For the morphing mesh it is almost the same. The only thing which changes is the entry for dynamicFvMesh. The basic difference to the tutorial described in [5] is that the motion is constrained in the y-plane instead of along the z-axis.

motionSolverLibs (sixDoFRigidBodyMotion);

motionSolver sixDoFRigidBodyMotion;

displacementLaplacianCoeffs

{

diffusivity uniform 1;

}

dynamicFvMesh dynamicOversetFvMesh;

dynamicOversetFvMeshCoeffs { // layerRelax 0.3; }

sixDoFRigidBodyMotionCoeffs {

accelerationRelaxation 1.0; accelerationDamping 1.0;

patches (walls); innerDistance 1.0; outerDistance 1.1;

mass 0.03575; centreOfMass (-0.016 0.0 0.0); momentOfInertia (4.3472E-07 1.144E-08 4.3472E-07);

g (0 -9.81 0); rho rhoInf; rhoInf 14817.; report on;

solver

{

type symplectic;

}

constraints

{

yPlan

{

sixDoFRigidBodyMotionConstraint plane;

normal ( 0 1 0);

}

yAxis

{

sixDoFRigidBodyMotionConstraint orientation;

centreOfRotation (0 1 0);

}

}

restraints

{

verticalSpring

{

sixDoFRigidBodyMotionRestraint linearSpring;

anchor (-0.016 0.0 0.0);

refAttachmentPt (-0.016 0.0 0.0);

stiffness 32.83;

damping 0.00;

restLength 0;

}

}

}

References

[1] Sanjay Mittal et al. Lock-in in vortex-induced vibration. Journal of Fluid Mechanics, 794:565–594, 2016.

[2] TL Morse and CHK Williamson. Prediction of vortex-induced vibration response by employing controlled motion. Journal of Fluid Mechanics, 634:5, 2009.

[3] Marie Pomarede, Elisabeth Longatte, and Jean-Franc ̧ois Sigrist. Bench- mark of numerical codes for coupled csd/cfd computations on an elemen- tary vortex induced vibration problem. In ASME Pressure Vessels and Piping Conference, volume 43673, pages 537–546, 2009.

[4] TK Prasanth and Sanjay Mittal. Vortex-induced vibrations of a circular cylinder at low reynolds numbers. Journal of Fluid Mechanics, 594:463, 2008.

[5] Diogo Sabino, David Fabre, JS Leontini, and D Lo Jacono. Vortex- induced vibration prediction via an impedance criterion. Journal of Fluid Mechanics, 890, 2020.

[6] Linwei Shen, Eng-Soon Chan, and Pengzhi Lin. Calculation of hydro- dynamic forces acting on a submerged moving object using immersed boundary method. Computers & Fluids, 38(3):691–702, 2009.

[7] SP Singh and S Mittal. Vortex-induced oscillations at low reynolds num- bers: hysteresis and vortex-shedding modes. Journal of Fluids and Struc- tures, 20(8):1085–1104, 2005.

[8] CHK Williamson and R Govardhan. Vortex-induced vibrations. Annu. Rev. Fluid Mech., 36:413–455, 2004.